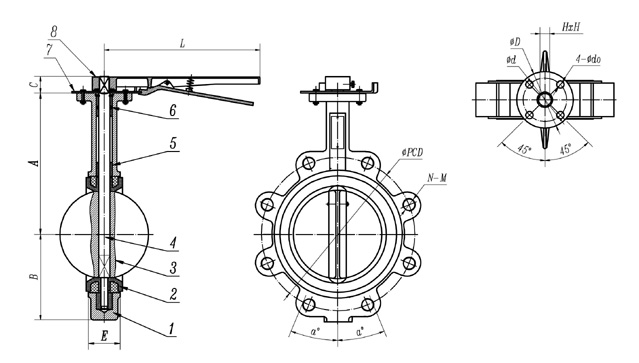

Lug Butterfly Valves

No.:DQL0101

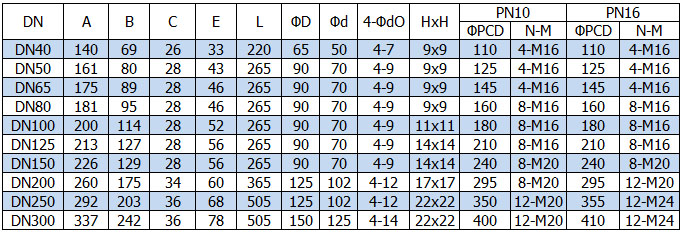

1. Working pressure:16bar.

2. F to F DIM.ACC.to ISO5211/EN558-1 Basic series 20.

3. Top-Flange ACC.to ISO5211.

4. Fitting between flanges EN1092-2 PN10/16.

Lug butterfly valves are consists of rubber seat, carbon steel or stainless steel disc and stem. they are used on water supply and drainage and gas pipelines, such as foodstuff, medicine, chemical industry, petroleum, electric power, textile, papermaking etc, to be worked as adjusting and the closure device.

- Body lining of rubber vulcanization ensure a stable driving torque.

- Ends of body rubber vulcanization adopt water line to fulfill various forms of the flange sealing requirements.

- Apply to different standards of valve installation.

- Tooth disc positioning meet different mouth degrees of flow control.

- Lever locking device ensure a safe location or a lock up state.

- Another replaceable seat(no back of chair seat), can meet the sealing part to change regularly. More greener.

- Sample and compact construction, small in size, light in weight, easy to install and maintain.

- Minimized operating torque, energy saving, you can choose lever, worm gear, pneumatic apparatus, electronic apparatus or combination driving operation according to working requirements.

- Professional design, high flow rate, low flow resistance.

- Suitable medium: fresh water, waste liquid, seawater, vapor, food, medicine, oils, acids, alkalis, salts, etc. no leakage under rated pressure.

- Applicable of flange: replaceable seat(with back) use the special butterfly valve flange for installation; replaceable seat(without back) or valve body line with rubber seat apply to professional butterfly valve flange or welded flange, etc. various flange installation.

- The combination driving way: can extension rod or wrench to realize manual, mechanic operating, pneumatic, electric operating style for under shaft working. Still can realize motor and electric combinations(electric actuator installed in connection plate which also connection with gear box)